Wood finishing is an art that requires patience, skill, and attention to detail. From selecting the right stain to applying the perfect topcoat, every step plays a crucial role in achieving a flawless finish. However, despite our best efforts, orange peel – that bumpy, uneven texture resembling the skin of an orange – can sometimes affect the final result. In this guide, we’ll dive into the causes of orange peel in wood finishing and explore the best techniques to eliminate and prevent it.

Understanding Orange Peel

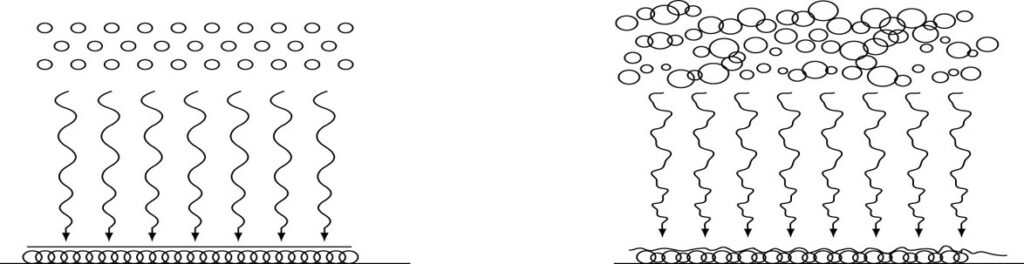

Orange peel is a common issue encountered in wood finishing, characterized by a textured surface resembling the skin of an orange. It occurs when the finish dries unevenly, resulting in tiny ripples and bumps across the surface

Several factors contribute to the formation of orange peel, including

Application Technique

Applying too much finish or using improper application techniques such as spraying at incorrect pressure or holding the gun too far from the surface can lead to orange peel.

Temperature and Humidity

Extreme temperatures and high humidity levels can affect the drying process of the finish, causing it to dry too quickly or slowly, leading to orange peel.

Product Characteristics

Certain finishes, especially solvent-based ones, may be prone to orange peel due to their viscosity and drying properties.

Eliminating and Fixing Orange Peel

Sanding

One of the most common remedies for orange peel is sanding. Begin by using a fine-grit sandpaper (e.g., 400-grit) to carefully sand the surface, focusing on the areas with orange peel. Gradually move to finer grits (600-grit or higher) until the surface becomes smooth and uniform. Be cautious not to sand through the finish or damage the wood.

Leveling Agents

Leveling agents, such as retarders or flow additives, can be added to the finish to slow down the drying process and allow the finish to level more evenly. Consult with your paint manufacturer for recommendations on suitable leveling agents for your specific finish if this is the route you want to take.

Wet Sanding

Wet sanding involves sanding the finish with a fine-grit sandpaper (e.g., 1000-grit or higher) while keeping it moist with water or a lubricant like mineral spirits. This method helps to minimize dust and clogging of the sandpaper while achieving a smoother finish.

Buffing and Polishing

After sanding, buffing and polishing can further enhance the smoothness and gloss of the finish. Use a high-quality polishing compound and a buffing pad to gently buff the surface in circular motions until the desired shine is achieved.

Proper Application

Prevention is always better than cure. To avoid orange peel in the first place, ensure proper application techniques, including maintaining the correct spraying distance, applying thin and even coats, and working in optimal temperature and humidity conditions.

You can effectively eliminate and prevent orange peel in wood finishing by employing the right techniques and precautions, despite it being a frustrating setback. Whether through sanding, leveling agents, or proper application, achieving a smooth and flawless finish is within reach. By understanding the causes of orange peel and employing the appropriate remedies, woodworkers can ensure that their finished pieces showcase the beauty of the wood without any unwanted texture. So, embrace these tips, refine your finishing skills, and say goodbye to orange peel for good!

Excellent product, shipping was really fast.

It works really well at maintaining good material flowl regardless of the orientation of the spray gun or the amount…

A very effective tool in allowing me to use small quantities of material without compromising flow and coverage

It was what I needed

South Coast Quality Painting, INC. This spray gun is great! It's easy to use and gives a great finish. Totally…